Showroom

The Diamond Segment BIT Abrasives

offered by us are diamond segment used on the gangsaw blade. The shape

is mainly isosceles trapezoid and rectangular. The diamond segment is a

functional part of a metal-bonded diamond tool. The metal-bonded diamond

tool can be a metal-bonded diamond saw blade. There are three methods

to weld and braze diamond segments onto the saw blade: silver brazed

diamond blade, wholly sintered diamond blade and laser welded diamond

blade. The offered Diamond Segment BIT Abrasives are offered by us in

various types. They are easy to use and made for industrial

applications.

Diamond Resin Bond Abrasives is the

name describes, is a combination of resins and fillers pressed under

heat and pressure that are easily dressed to angle forms, straight

forms, and special radius forms. The diamond abrasive is widely used in

resin bond diamond grinding wheels in China. Its grains are mostly

needle-like, irregular crystal shape, low strength, high brittleness,

rough surface but sharp grinding. The diamond is polycrystalline diamond

superhard abrasive, mainly used in the production of resin bond diamond

grinding wheel. The offered Diamond Resin Bond Abrasives are made for

use in the various industries and commercial applications.

We

are offering here the Synthetics Bond Abrasive that is composed of an

abrasive material contained within a matrix, although very fine

aluminium oxide abrasive may comprise sintered material. This matrix is

called a binder and is often clay, a resin, a glass or a rubber. This

mixture of binder and abrasive is typically shaped into blocks, sticks,

or wheels. With the application of chemically resistant synthetic rubber

on butterfly valves, the performance of butterfly valves is improved.

The offered Synthetics Bond Abrasive is offered by us that is made for

use in the various industries and commercial purposes.

The offered Diamond Pads are offered in various types that are the only impregnated diamond pads in the world that contains both diamonds and Ferron, which is the only substance that can scratch a diamond. Pads are professional grade diamond impregnated pads that can be used dry or wet. The pads can be applied to granite polishing, marble polishing and concrete. To smooth the concrete after grinding with a turbo-cup wheel, or to perform light grinding on concrete that does not have embedments in it, coarse resin diamond pads are used. They are very efficient and useful.

A 5 Extra Final Polisher For Marble is

offered by us that enhances the shine and smoothness of the marble

floor. For this diamond floor polishing pads with grit 100 and 200 are

used and are effective. Polishing gives shining effect to the marble

floor. For marble floors in good condition, polishing is enough to bring

back the shine. Marble polishing in the sense of making a dull or honed

marble shiny is not done by applying a chemical or polish. The offered 5

Extra Final Polisher For Marble is offered by us for efficient use in

the various commercial applications.

The supplied Final Polisher For

Granite LUX is offered by us that is the best polishing agent for

granite and other natural stone surfaces. Polishing granite is often

seen as a way of beautifying the stone. However, it is actually part of

proper maintenance. When people polish stone, fingerprints and streaks

are less likely to form and cause issues. In order to reach the desired

finishing, granite slabs are run through a series of progressively finer

diamond polishing pads in a slab polishing machine. The offered Final

Polisher For Granite LUX is made for use in the various industries.

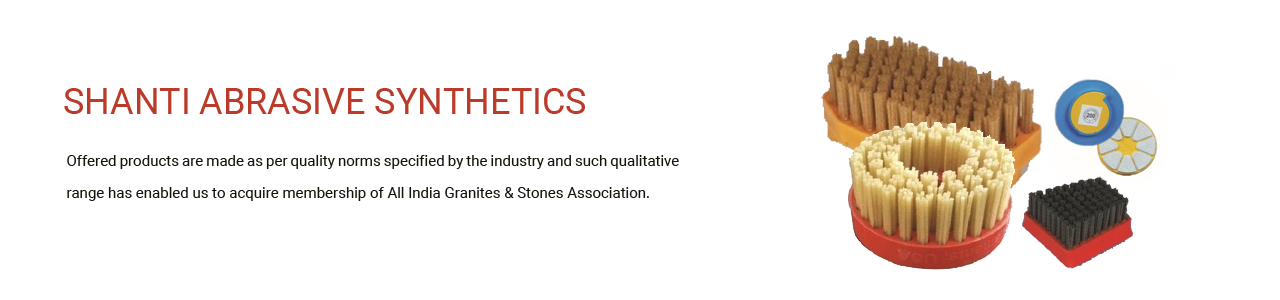

There are Diamond And Silicon Abrasive

Brushes offered by us that provide additional strength compared to

straight brushes and are commonly used where a knotted brush's impact

would alter the working surface. Abrasive brushes are made with coarse

strands of material and are used with power tools to polish, debur,

clean, or buff surfaces. Silicon abrasive brush is made of high quality

silicon carbide or steel wire for granite matt-surface making on.

Theyre almost spark free and with lower thermal impact, reduce the risk

of workpiece burn. The Diamond And Silicon Abrasive Brushes are very

efficient and useful.

We

are offering here the Buffing Felt & Powders that are commonly used

in conjunction with a shaped, chamois leather buffer to mildly abrade

(burnish) the nail plate so that a smooth, shiny surface was produced.

It produces a high gloss shine on most stone, particularly marble. These

compounds are used to buff iron, steel, stainless steel and some

aluminum and brass castings. They are used to smooth metals in many

industries to give a clean and polished finish and improve the polishing

and buffing wheel's effectiveness. The offered Buffing Felt &

Powders are made for use in the various commercial applications.

The Magnesite Abrasives are magnesite silicon carbide bonded for marble calibration and grinding. With aggressive silicon carbide inside, this magnesite abrasive keeps sharp and performance consistent with maximum performance. Abrasives are suitable for rough calibrating and smoothing for common granite & marbles in the automatic polishing machine. Abrasives are best for fast leveling of marble, stone, granite & ceramic surfaces. Magnesite is a magnesium carbonate mineral with a chemical composition of MgCO3. It is named after the presence of magnesium in its composition. The Magnesite Abrasives are offered by us that are made for industrial applications.

|

SHANTI ABRASIVE SYNTHETICS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |